We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Galvanised Steel Wire Rope Grips DIN 741

These hot-dipped galvanised steel wire rope grips, also known as bulldog grips, have been made to DIN741 specification.

They allow you to easily create loops and secure wire rope without the use of specialist tools. We recommend that you use three bulldog grips to secure each end, as displayed in the first picture.

These galvanised steel DIN741 grips come in various sizes to suit most diameters of rope. They are available in sizes to suit 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 19mm, 22mm and 25mm wire rope, and are sized to allow the wire rope to be doubled back through the same grip.

A simple wire rope shop guide on how to use and fit your steel wire rope grips

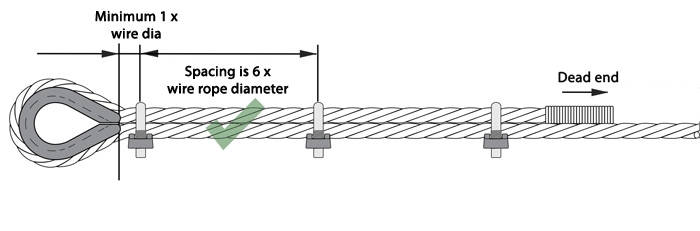

- Din741, Din1142 and US Federal Steel Wire Rope Grips should be spaced six wire rope diameters apart to give adequate holding power (eg. 5mm wire rope = 30mm distance between grips)

- We recommend a minimum of 3 grips per end

- They should be tightened before the rope is placed under tension

- After the load is placed on the wire rope, tighten the clamps again to take care of any lessening in rope diameter caused by tension of the load

- Regularly check the nuts ensuring they are still fastened tightly

- The Wire Rope Grips are sized like for like, eg. If you have 5mm wire rope then buy 5mm grips, each grip allows that diameter of wire to pass through twice to form a loop

- It is generally accepted that you should achieve 50% of the wire rope breaking load as a guide to holding power

Please take note of the above image, the dead end of the wire (cut end) should always be at the top, the live end should always be at the bottom on the saddle.